AutoMate your load carrier movements

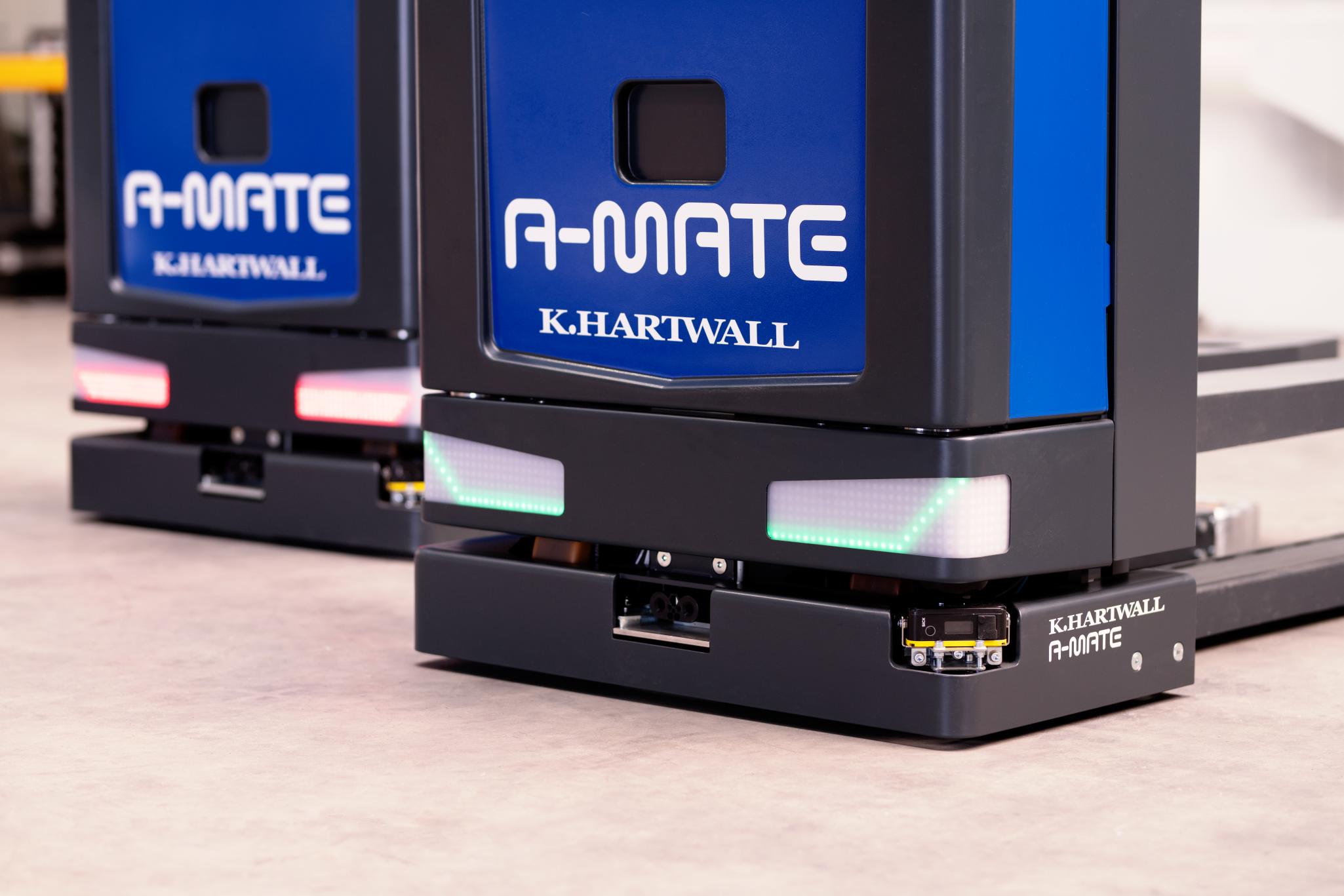

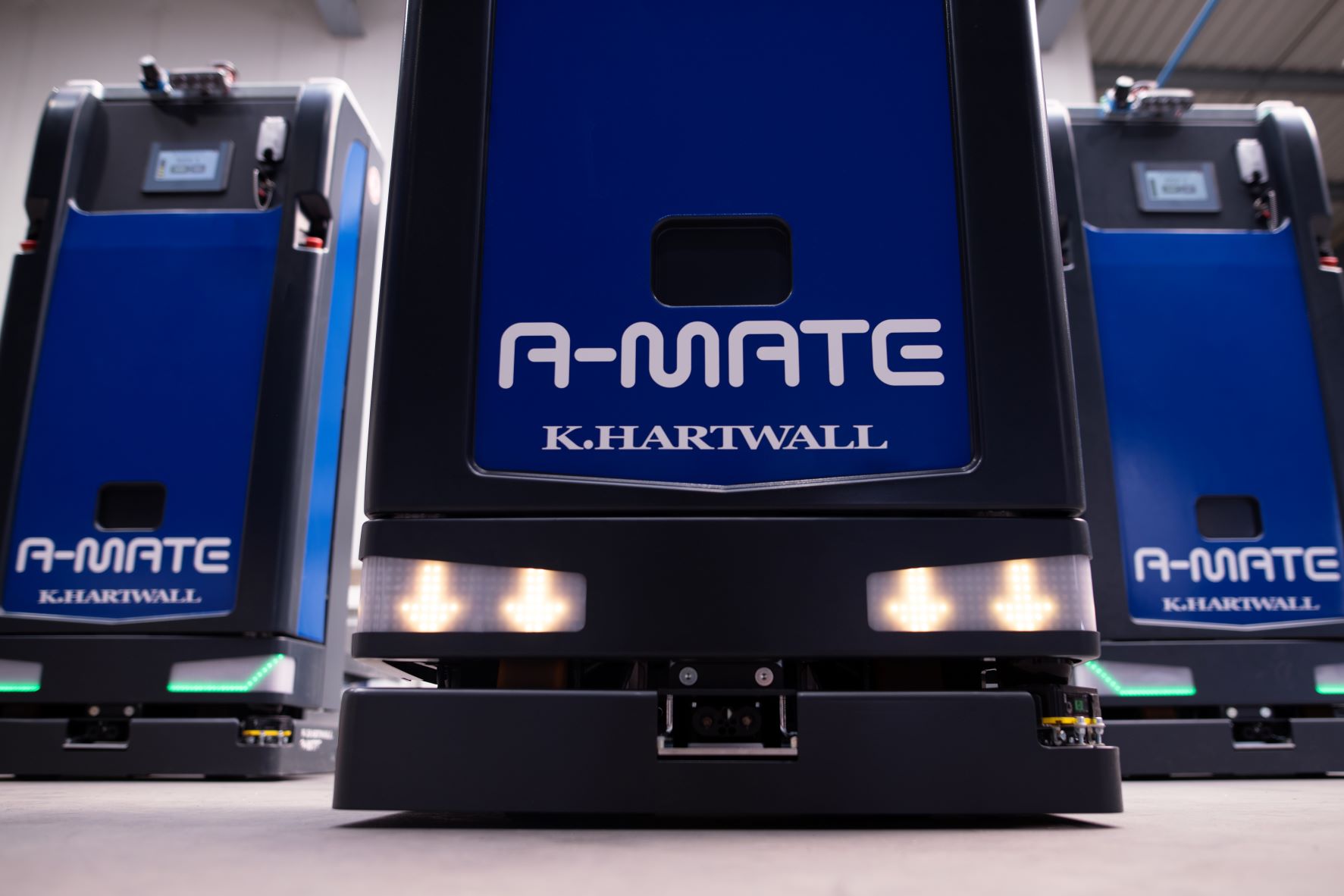

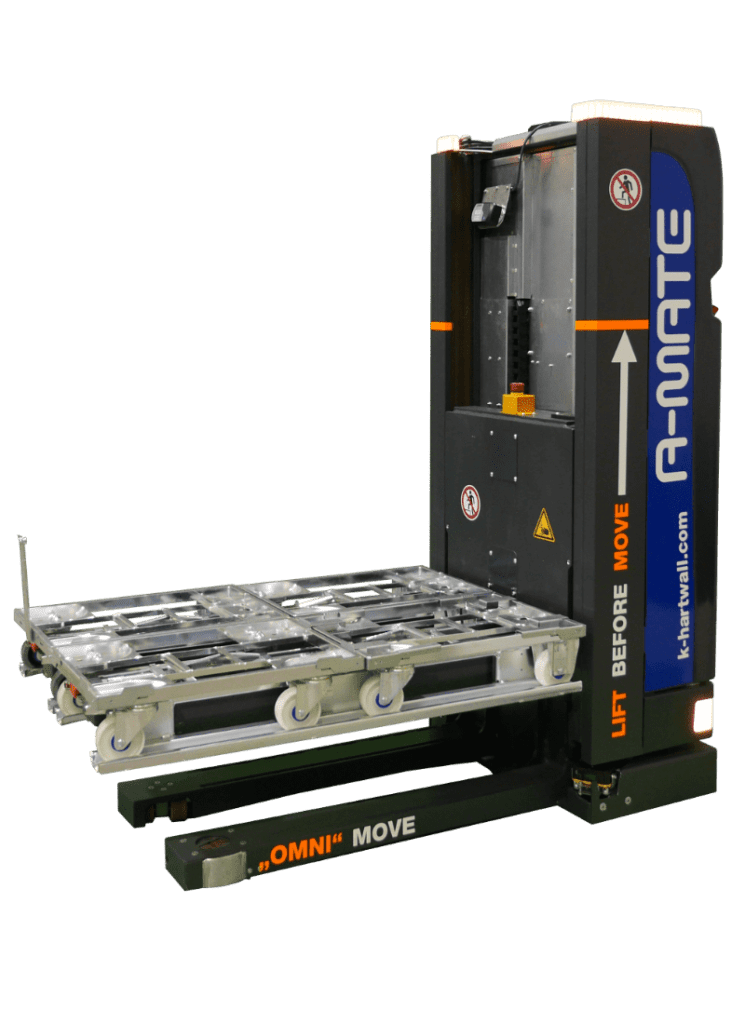

A-MATE® FreeLift

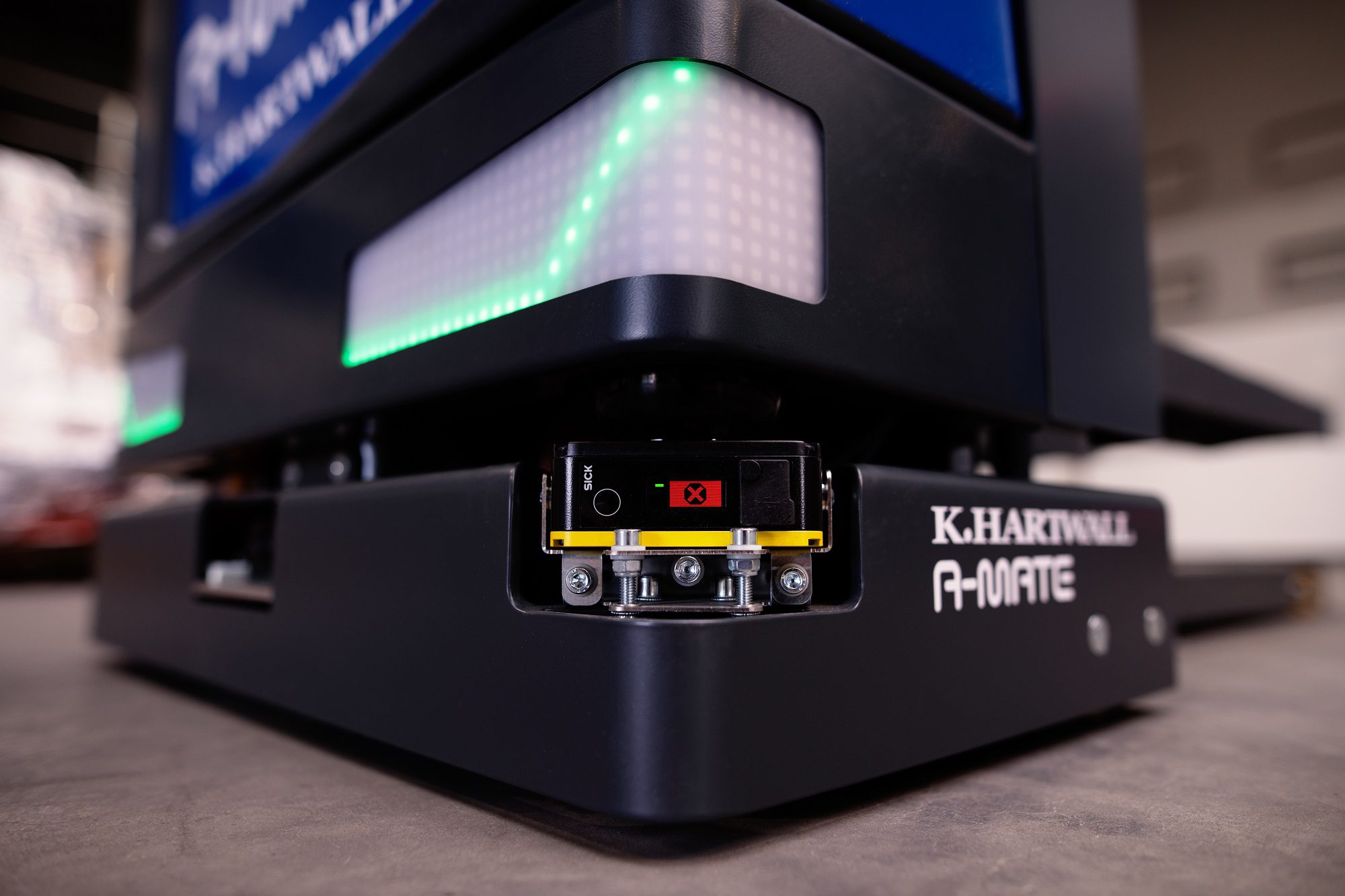

A-MATE® FreeLift is an intelligent mobile robot designed to transport logistic units such as pallets and containers in production and logistics environments such as warehouses and sorting centers.

As a Automated Guided Vehicle (AGV) it is completely autonomous and does not need an on-board operator or driver.