A-MATE®

AGV mobile robots

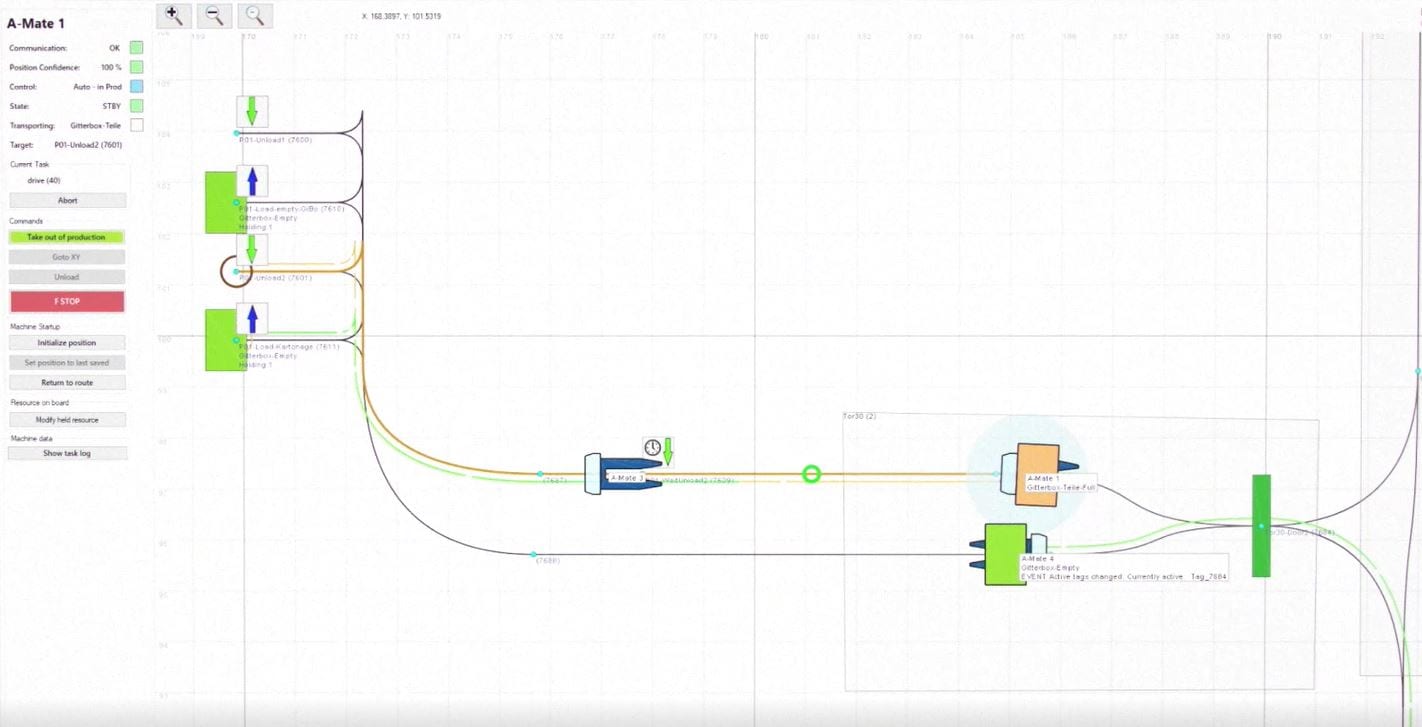

Our Automated Guided Vehicles (AGVs) A-MATE® offer you a new way to reduce costs and increase efficiency in your logistics processes.

AGVs and mobile robots automate the product flow in demanding environments, such as factories, warehouses and sorting centers, and allow you to decrease your dependency on skilled labor, process errors and the risk of accidents.

Take a look at the next generation of AGVs and rewrite the future of logistics with us!